Experience

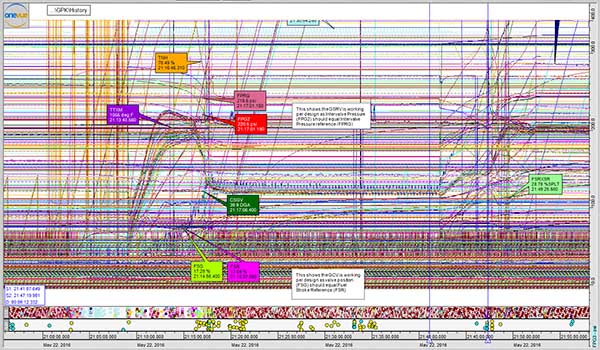

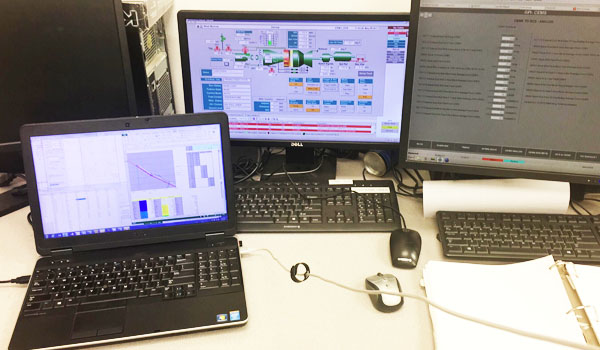

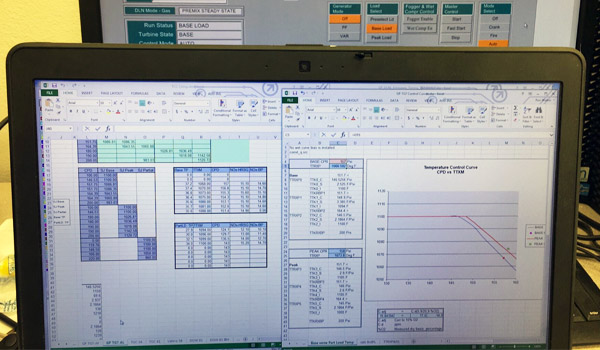

From nuclear, medium and small steam turbines to all gas turbine frame sizes, we perform field services, upgrades and modifications of all types, along with DLN tuning, software modifications, valve calibrations, exhaust temperature control specification checks, outage maintenance or emergency support, we have the experience you need.

Main Office Location

Main Office Location